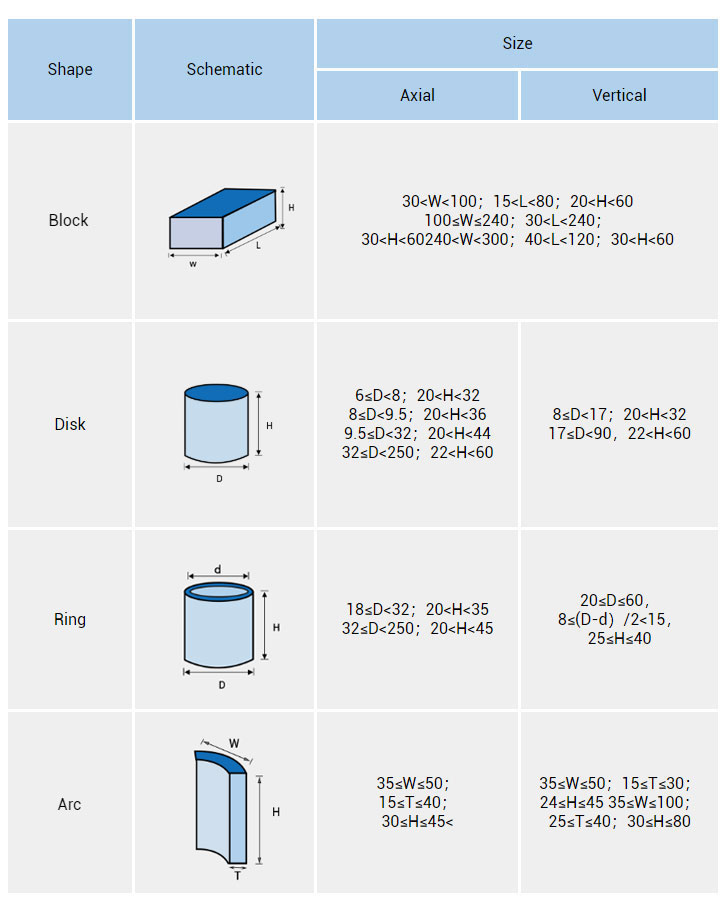

| Shape | Schematic | Size | |

| Axial | Vertical | ||

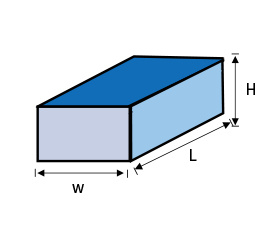

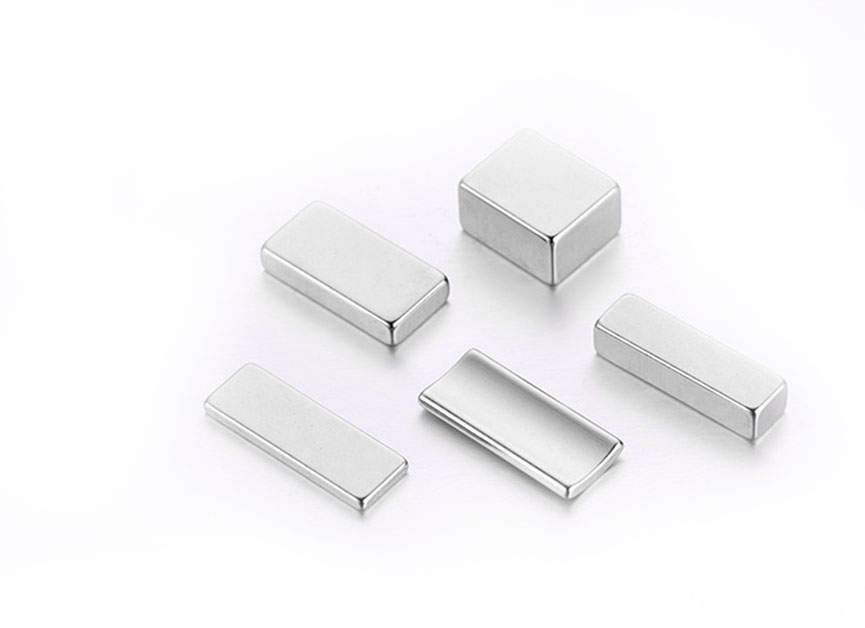

| Block |  |

30<W<100;15<L<80;20<H<60

| |

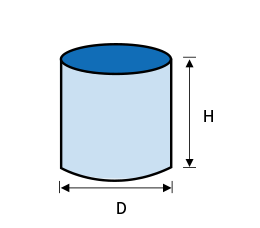

| Disk |  |

6≤D<8;20<H<32

| 8≤D<17;20<H<32 |

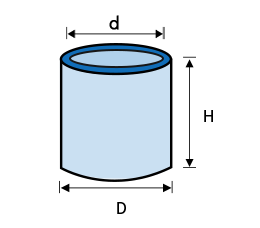

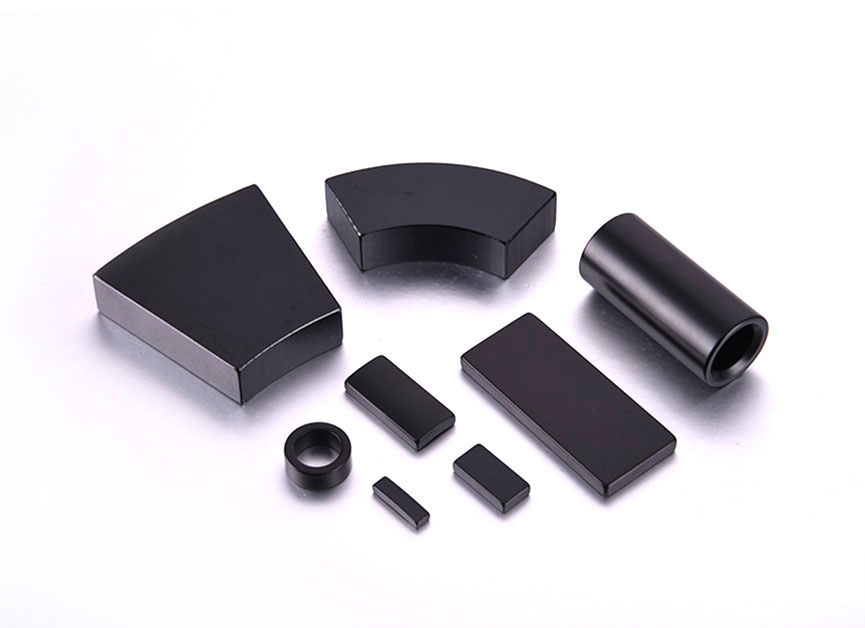

| Ring |  |

18≤D<32;20<H<35

| 20≤D≤60 |

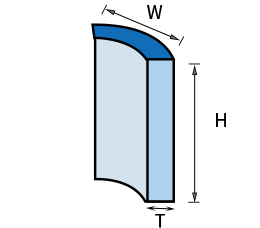

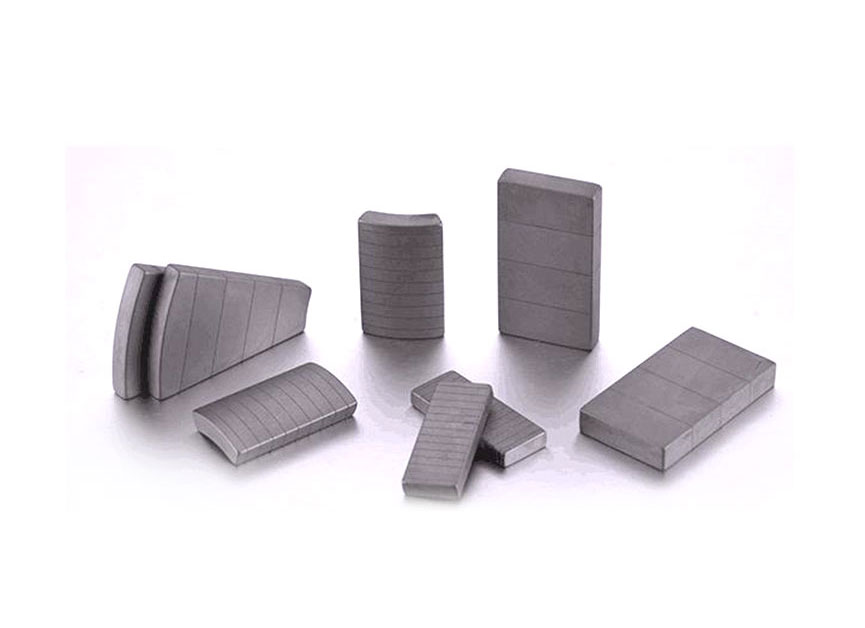

| Arc |  | 35≤W≤50; 15≤T≤40; 30≤H≤45;

| 35≤W≤50;15≤T≤30;

24≤H≤45 |

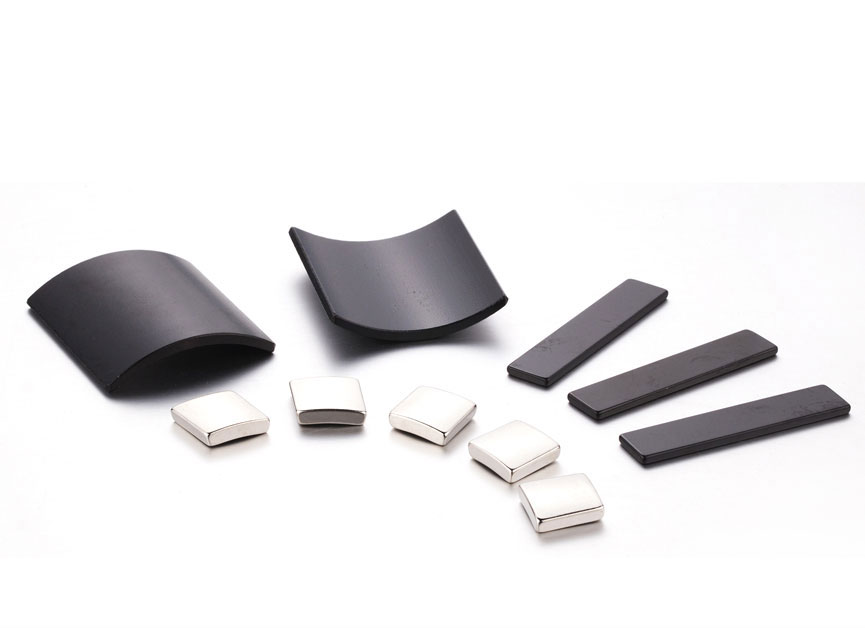

Rare earth magnets have been around for a very long time, though it is hard to pinpoint when they were first invented. They can be seen in everything from watches to clothing but were primarily developed for use on automobiles. In addition to being used in the automotive industry, many other industries have found great success in using rare earth magnets in their equipment. This includes medical, aerospace and manufacturing industries. There are a number of different types of magnets available, including ferromagnetic and magnetite.

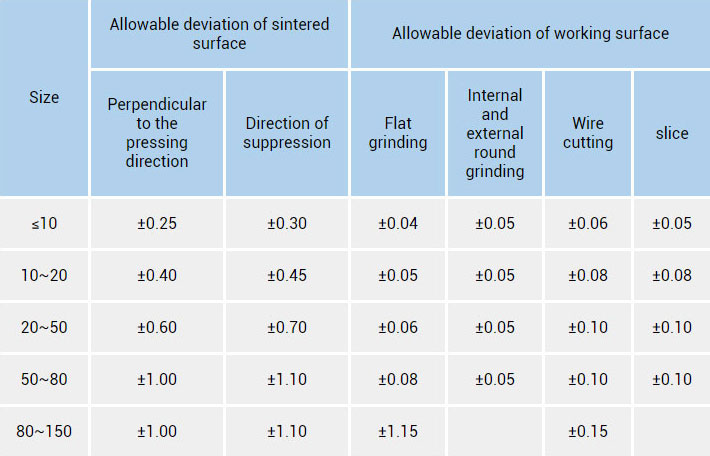

Dimensional deviation (unit: mm)

| Size | Allowable deviation of sintered surface | Allowable deviation of working surface | ||||

| Perpendicular to the pressing direction | Direction of suppression | Flat grinding | Internal and external round grinding | Wire cutting | slice | |

| ≤10 | ±0.25 | ±0.30 | ±0.04 | ±0.05 | ±0.06 | ±0.05 |

| 10~20 | ±0.40 | ±0.45 | ±0.05 | ±0.05 | ±0.08 | ±0.08 |

| 20~50 | ±0.60 | ±0.70 | ±0.06 | ±0.05 | ±0.10 | ±0.10 |

| 50~80 | ±1.00 | ±1.10 | ±0.08 | ±0.05 | ±0.10 | ±0.10 |

| 80~150 | ±1.00 | ±1.10 | ±1.15 | ±0.15 | ||

| Variation type | Variation type | Basic size(mm) | Deviation | |

| Parallelism | Working surface room | One half of the tolerance value between the two planes | ||

| Verticality | Between sintered surfaces | Random | 90°±1° | |

| Between machined surface and sintered surface | 90°±1° | |||

| Working surface room | 90°±0.15° | |||

| Concentricity | Between sintered surfaces | Outer diameter | ≤14 | ±0.35mm |

| 14~24 | ±0.60mm | |||

| 24~40 | ±0.80mm | |||

| 40~60 | ±1.100mm | |||

| 60~80 | ±1.150mm | |||

| 80~180 | ±2.00mm | |||

| Working surface room | Random | ±0.08mm | ||

ELECTROACOUSTIC FIELD

MOTOR FIELD

EQUIPMENT

MEDICAL INSURANCE

HOUSEHOLD APPLIANCES

OTHER

VACUUM ALUMINIZING

PHOSPHORIZATION

EPOXY

GALVANIZING

NICKEL-PLATED COPPER NICKEL

EVERLUBE

Please complete the form below and one of our team will get back to you as soon as possible.